LED Troubleshooting - Soldering

If are cutting and re-connecting your LED Strip lights by soldering wires to the strip there are a few important soldering dos and don'ts to be sure that your LED Strip Lights will work properly and to their expected lifetime.

Soldering Dos and Don'ts

DO

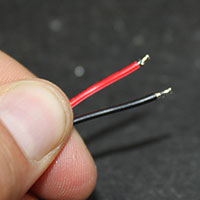

DO Use Straight Soldered Wires

Using short straight soldered wire leads is very important when creating a clean efficient soldered connection to your LED strip light. Doing so will minimize the risk of an electrical arc by two stray wires touching one another.

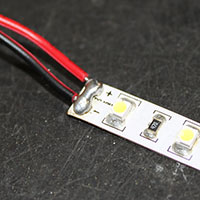

DO Use Small Soldered Connections

Having clean and small solder joints is important to any professional quality solder work on your LED Strip lights. It is important to have clean solder joints that are not touching one another to avoid electrical arcing and to be sure that electrical current is effectively passing through.

DO Heat Shrink Over Connection

You should always use heat shrink over your finished solder joint to be sure that the joints are not exposed to any outside elements or especially when you are mounting your LED Strip to metal. It is not 100% necessary but definitely recommended.

DO Use Proper Soldering Temperature

When soldering you need to be sure that your soldering temperature is between 600°-650° in order to fully melt the solder without burning the PC board or electrical components on the LED strip light. You must be certain not to leave the solder iron on the strip any longer than 5-10 seconds at a time.

DON'T

DO NOT Use Frayed Unsoldered Wire

If you use long frayed and unsoldered wire leads when making a soldered connection to your LED Strip lights this will severely increase the risk of an electrical arc and potential damage to your LED Strip Light.

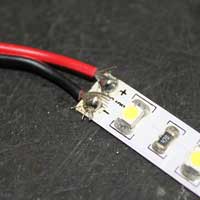

DO NOT Use too Much Solder

When soldering your LED Strip Light it is important to not use too much solder and regularly clean your soldering iron. When your positive and negative solder joints touch one another this will cause an electrical arc that will eventually cause damage to your strip light.

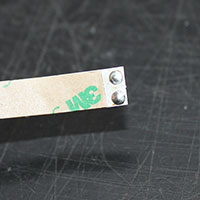

DO NOT Leave Copper Pads Exposed

When you leave the copper pads on the bottom of your strip lights exposed and mounting them to any type of metal, your lights will not work because the copper pads will create an electrical arc and in turn most likely damage your strip lights over time.

DO NOT Overheat Solder

If your soldering iron is too hot over the recommended 650° and you leave it on a joint over 10 seconds your LED Strip light will most definitely be damaged. As you can see from the picture over heating a solder joint will cause damage to that section of LEDs.