LED Troubleshooting - Wiring

Wiring mistakes are the most common of all LED lighting issues. Typically if your LED lights simply "don't work" it is not because the products are defective but due to a basic wiring mistake or overlook. If you are having issues getting anything to work in your LED installation or your lighting is inconsistent go over this trouble shooting guide for some pointers on resolving your issue. If you are sure that your wiring is correct read our Multimeter troubleshooting guide on tips for testing the input and output of your LED Power Supply.

Common Wiring Mistakes

When troubleshooting the wiring of your LED installation it is important to double and even triple check every connection, even the most skilled electricians can make a simple wiring mistake. Be certain that your wires are exposed and making contact with the correct wires or ports on your LED Lighting products. If you have wires crossed up or touching you may be at risk for electrical shock or product damage. Click the image to the right to check common wire colors and be certain that you have your polarity correct when wiring. If you are not certain the polarity of your wires use a multimeter to test.

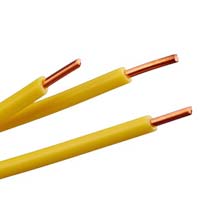

A very common wiring mistake that is easily overlooked is the possibility of loose or obstructed wires in your LED installation. Typically if your lights simply don't work or you are missing a color on your RGB installation this is the case. If your wires are not stripped back far enough or you push them too far into a connector it will give the illusion of a secure connection when really there is no connection at all the connector is only clamping on the pvc wire coating. See the picture to right for an illustration of this example. This is why it is important to double and even triple check your wiring installations because even if a wire looks like it is connected it may not be.

Frayed or overlapping wires are another common wiring mistake. If you are not using clean and straight wires then you are probably going to experience a wiring issue sooner or later. All it takes is a single strand of wire touching another wire or a conductive surface to put your LED installation at risk for an electrical short or mixed color effects. When working with LED modules be sure that the end of your module string does not have bare wires touching. When soldering be sure that your wires are clean and straight and never touching eachother and be certain to never overload a wire connector that is designed for a single wire input.

Voltage drop is a very common LED installation issue and it all has to do with the layout of the wiring. If you are experiencing voltage drop it is most likely due to the fact that you have wired your LED installation in a serial connection rather than a parallel connection. Think of a parallel connection as each 10-20ft section of your LED lights running independently back to the power supply rather than linking them in a single series. Parallel connections will always give you the most even and consistent lighting output due to less voltage drop with less serial connections. See the illustrations at the bottom of this guide for a visual reference on the difference between the two types of connections.

Wiring Dos and Don'ts

DO

DO Use Stranded Wire

With stranded wire you get more intimate contact, thus reducing voltage drop and power losses. Poor connections can rob a system of a significant portion of the power being produced. Stranded wire will compress and flatten out which increases the contact area. This reduces the voltage drop and minimizes heating at the connection.

DO Use Clean, Straight Wire Leads

Having clean and straight wires is important to any LED installation. If your wires are clean and straight you will get the best possible connection and reduce voltage drop. If you want you can solder the ends of your wires to keep them together and know you are getting sufficient contact on your connections.

DO Heat Shrink or use Connectors

When connecting two wires together it is always best to use the proper wire connectors or solder your wire together and apply heat shrink to protect. There are a variety of wire connectors for different types of wires so it is critical that your connectors are made for the wire you are using and securely fastened.

DO Use Wire Splitters

A common mistake people make when wiring LED lighting products is trying to simplify the installation by jamming 10 wires into a wire nut or phoenix connector. Instead of doing this it is better to use multiple wire splitters, terminal blocks, or solder wires together to split your wires, rather than try and overload a wire connector which can be a serious fire hazard.

DO Use Parallel Connections

When installing larger LED installations or installations with a lot of wire running to multiple locations it is a must to wire your lights in parallel to the controller or power supply to reduce voltage drop. Think of a parallel connection as your LED lights running independently back to the power source, or run a home run wire to your power supply and splice into that wire at your different wiring locations. Test with a multimeter to check for voltage drop.

DON'T

DO NOT Use Solid Wire

When using solid wire in a low voltage system you will notice, at best, that you will have three small contact areas between the solid wire and the device connection when using a typical screw down terminal. This also applies to power distribution blocks or wire nuts where you have only two contact areas, that can cause a heating connection.

DO NOT Fray Wire Leads

When your wires are frayed and going in all directions you are at risk of multiple wiring issues. First of all you will notice voltage drop if only a few pairs of your stranded wire are making electrical contact, secondly you are putting your installation at risk for an electrical short and potential fire hazard.

DO NOT Leave Bare Wire Splices

When wiring your LED Lighting project it is very important to not leave any of your wire splices exposed. Leaving bare wire splices exposed puts your installation at risk for an electrical short and potential fire hazard. Always use proper wire connectors and never leave bare wire splices exposed.

DO NOT Overload Wire Connectors

Overloading wire connectors is the most common mistake when installing LED lighting products. When there are too many wires in a connector that is designed for a single wire this can cause serious fire hazard issues if a short occurs or the wires begin to arc. It can also cause voltage drop issues if some wires have a more secure connection than others.

DO NOT Use Serial Connections

For first time LED installers serial connections seem like common sense when wiring your LED lights. What people don't realize is that each little LED and it's components takes a bit of voltage away from the next in a series. So the longer you run your LED lights in a series the more voltage drop that is going to occur and the less even your lighting will be. If you are installing lights over 20ft or in multiple locations always use parallel connections.